|

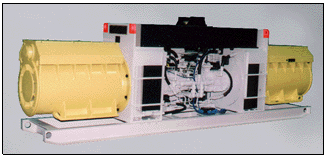

Hydraulic aggregates |

|

Choosing the most suitable type of drive is important when moving heavy loads with winching systems. One option is to use hydrostatic gearings (drives), particularly if cost-efficiency of the overall solution is important and variable tensile forces and/or infinitely variable cable speeds are required. The GH series sets new standards in terms of safety and functionality and thoroughly impresses with its solid build quality. The hydraulic aggregates operate in a closed circuit with primary adjustment and are designed as hydrostatic remote gearings which are also available as special versions with electric remote control. They are equipped with swash plate pumps (with negative tilt) and enable infinitely variable output speeds for clockwise/anti-clockwise operation. A control lever is used to manually control the magnitude and direction of the pump flow. |

|

Additional technical information about our hydraulic aggregates is available on request. We are happy to make special arrangements to supply hydraulic aggregates which are not listed here. |

|

The pressure medium is generally cooled via air heat exchangers. On more powerful hydraulic aggregates additional water heat exchangers are also used. Here the water supply is controlled by a thermostatic valve. Flange motors are provided for operation of the hydraulic aggregates. All of the relevant connection dimensions and the technical data for the electric motor should be specified when ordering. |

|

In order to prevent overloading the flanged-on electric motors , all hydraulic aggregates can be equipped with a load valve which reduces the pivot angle of the pump accordingly until the maximum operating pressure is reached. |

|

The feed / rinsing pressure of the secondary circuit is monitored automatically. The installation is switched off if the pressure drops below an adjustable lower limit. The fluid level of the pressure medium is checked with the aid of an integrated level monitor. The variable displacement pumps used are equipped with a pressure cut-off on both sides. When the maximum operating pressure is reached the pump delivery is reduced to the volume flow required to cover any leakage. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

© 2006 Göllner Maschinenbau GmbH |