|

Centrifugal pumps |

|

Göllner multi-stage centrifugal pumps are designed for pumping dirty water. In this context. "multi-stage" refers to the connection in series of the individual impellers. This layout allows pumping volumes to be added with virtually no change to the pumping current. The pump itself has a modular design, meaning that the layout of the individual stages of our centrifugal pumps is identical. As a result, modifications to the pump to change the delivery rates can be achieved with cost-effective after-market solutions by increasing or decreasing the number of stages. |

|

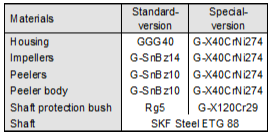

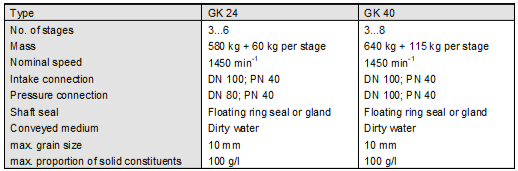

Thanks to the use of corrosion-proof and wear-resistant materials, our centrifugal pumps are not susceptible to the abrasive constituents in the dirty water. The application limits are given by a maximum permissible grain size of 10 mm (Ø of the solid particles in the conveyed medium) with a solid particle proportion of no more than 100 g/l. |

|

Our range includes two different series. Type GK 24 is available in versions with three to six stages. Type GK 40 is offered with three to eight stages. Both series are different in terms of pumping capacity and power requirements. Both of these parameters depend on the number of stages; in the diagrams the arrow points towards the greater number of stages. |

|

For the purpose of defining the number of stages, the power requirements of the pump are also of interest in addition to the delivery rate of the pump. Radial pumps have a minimal power draw with Q = 0 and should therefore be operated in the area of their maximum delivery rate. If the delivery rate is insufficient at this point then several pumps will need to used in parallel. Greater delivery rates can be achieved by increasing the number of stages or by connecting several pumps in series. We are glad to offer assistance when choosing individual centrifugal pumps and planning layouts. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

© 2006 Göllner Maschinenbau GmbH |